Simple Planter Maintenance Tips for Optimal Performance

As you have been patiently waiting to plant, we’ve been sharing planting and planter maintenance tips on our social media channels. We’ve compiled a list of those and added a few more! Even if you have started planting, these tips are still helpful. A small adjustment may have a big impact.

- Test your meters to ensure you are ready to go and know the vacuum and singulator adjustments before heading to the field. Visit your local Kinze dealer to have your mechanical and vacuum meters tested on the new Kinze T-4000 seed meter test stand.

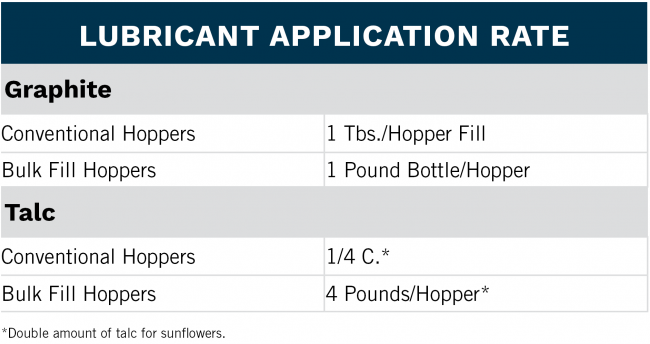

- Lubricate your meters. We offer graphite, an 80/20 graphite-talc mix, and standard talc.

- Make sure your electronics are up to date before heading to the field to ensure all performance enhancements have been installed. Click here to check current versions.

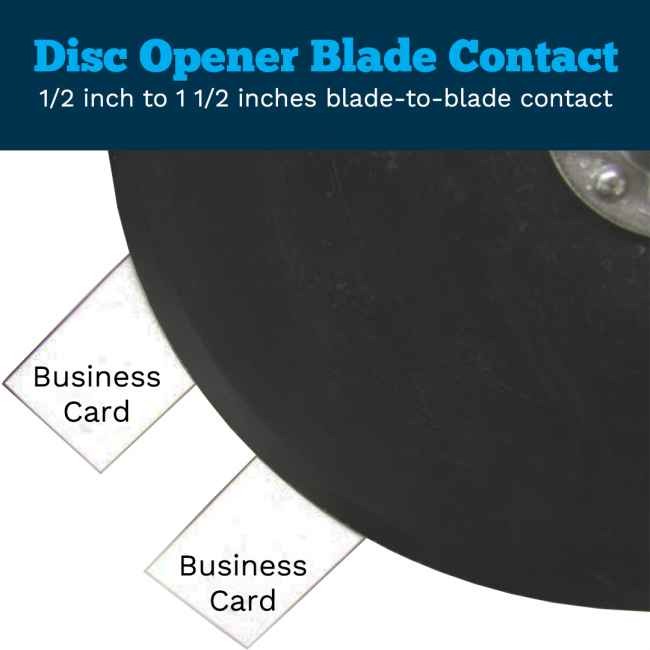

- There are two ways to check for proper opener disc blade-to-blade contact:

- Insert a business card in the upper opening and one in the lower opening. Slide the cards together until they stop. The distance between the cards should be a ½” to 1½”.

- Holding one blade while rotating the other blade against each other. If there is slight resistance, you are good to go. Error to the side of light contact.

- Tire pressure is critical to obtain desired population across the planter. Check tire pressures before heading to the field to ensure correct and consistent population.

- Use a level, aligning the top to the bottom of the disc opener blades. Once it is level, measure the distance from the bottom of the coulter blade to the top of the level. The blade should be 1/8-inch above the disc opener blade.

- Brush meter seed discs life expectancy is 100-200 row acres or when the grooves for each pocket are not clearly defined; the True Rate™ vacuum meter is 600-900 row acres.

- Gauge wheels should lightly contact opener blades in planting position. You can check this by raising the wheel up to the mid position and rotate the wheel to ensure it has light contact. Move shims from the inside of the gauge wheel arm to the outside to move the arm in. If you are out of shims to move, it is time to replace the gauge wheel.

- Having trouble in moist soils and your no-till coulters are moving too much dirt? Try a different coulter option. We offer a bubbled, ¾” fluted blade and 1″ fluted blade. The larger flute measurement, the more aggressive and more dirt the coulter will move. In a moist soil, a bubbled coulter or no coulter is your best option.

- Replace no-till coulter & opener blades when they are worn to a diameter of 14½” or smaller.

- Safety Tip: Ensure your safety warning lights and turn signals are working to ensure you are seen when traveling on the road.

Have a safe and successful #KinzePlant18!