Here’s What Our Customers Say

Season after season. Year after year. Decade after decade. We rely on you to tell us what we’re doing right and how we can improve. Read what real Kinze customers have to say about Kinze Manufacturing throughout the years.

Be Your Own Expert: the Brush Meter Breakdown

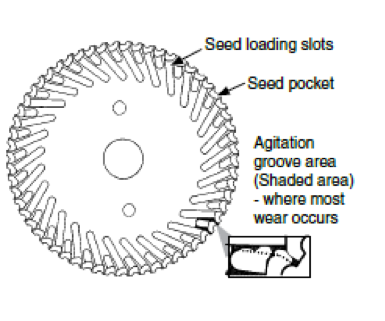

As planter technology continues to change, it’s important to know the in’s and out’s of your machinery so you can prevent problems before they arise. Plus, a little self-education makes you your own advocate for optimal yield numbers. With this thought in mind we want you to know the inner workings of one of the most important parts of your planter: the brush meter. A brush meter has four main parts:The Seed Disc – This is the only moving part in the meter. It provides singulation and loads the seeds on the disc. The average life expectancy is 100 to 200 acres per row. When the disc starts to wear out the population on that row or the entire planter will plant at a reduced rate. Upper Blue Brush – The main function of the upper brush is to hold one seed in each pocket on the outer edge of the meter....

In Kinze News

John Deere V. Kinze Part Four: So You Think You Have a Patent

Forty years ago, Kinze Manufacturing was just a small farm equipment startup near Williamsburg, Iowa. After developing several innovative products, the company was starting to attract the attention of farmers looking for ways to improve their farming efficiency. However, Kinze was also drawing the attention of the industry-giant, John Deere. The following is the fourth installment of a five-part series describing Jon Kinzenbaw’s early battles with John Deere - both in the field and in the courtroom. What started out as suit over row unit availability, eventually ended in a ruling that forever changed Kinzenbaw’s young company - and the ag equipment industry as a whole! This excerpt is from the book "Fifty Years of Disruptive Innovation" and is told in Jon’s own words. If you missed part one, part two or part three be sure to catch up on this blog series. So You Think You Have a Patent A very important practice in securing...

In News & PR

Planting the Seeds of Success

As a farmer and seed dealer, Jeff Olson knows the value of getting the most from each seed. As a way to maximize productivity, Olson, who farms near Madison, Minnesota, has used variable-rate planting technology for several years. Read more from farms.com

No-till Planter Tips for Spring Planting

Rugged terrain, heavy crop residue and soil compaction are challenges for all farmers using no-till planting methods. Yet, more and more farmers are moving to no-till practices, lured by higher yield potential. If done right, no-till planting can control soil erosion, reduce fuel and labor costs by eliminating extra trips across the field, and improve soil moisture and fertility. But successful no-till planting depends on making sure your planter is set up correctly. To start, it’s important your planter is in top condition so it can withstand the rigors of planting in previous crop residue. Essentially the first three steps of conventional cultivation are bypassed when practicing no-till, but you won’t gain any advantage if the equipment isn’t working properly. You can increase yield potential using no-till by following some simple maintenance checks to ensure your planter is ready to manage the residue and place seed with precise spacing and...

In Kinze News

John Deere V. Kinze Part Three: the Battle Lines Are Drawn

Forty years ago, Kinze Manufacturing was just a small farm equipment startup near Williamsburg, Iowa. After developing several innovative products, the company was starting to attract the attention of farmers looking for ways to improve their farming efficiency. However, Kinze was also drawing the attention of the industry-giant, John Deere. The following is the third installment of a five-part series describing Jon Kinzenbaw’s early battles with John Deere - both in the field and in the courtroom. What started out as suit over row unit availability, eventually ended in a ruling that forever changed Kinzenbaw’s young company - and the ag equipment industry as a whole! This excerpt is from the book "Fifty Years of Disruptive Innovation" and is told in Jon’s own words. If you missed part one or part two, be sure to catch up on this blog series. The Battle Lines Are Drawn Kinze Shortage Specialties Division It took three...

In Kinze News

Proudly Made in Iowa

Made in Iowa. We take pride in saying these words when talking about our grain carts and row crop planters that are built at our manufacturing headquarters in Williamsburg, Iowa. We champion our Midwest roots to anyone who will listen. Not just because of the pride factor, but also because building farm equipment in Iowa translates to several benefits to local farmers. 1. Faster response to demandOur dealers will be able to get you the exact grain cart or planter that you want quickly. While it might take months for other companies to restock the in-demand items of the season, we are prepared to fill orders in a timely manner. 2. Customizable solutions to customers’ needsSearching for something specific? Just look to our 3000 Series planter model as a prime example. In the 3000 Series, you can find six different row sizes available to meet your field needs. If your local dealer doesn’t have...

In Kinze News

John Deere V. Kinze Part Two: a Chance Worth Taking

Forty years ago, Kinze Manufacturing was just a small farm equipment startup near Williamsburg, Iowa. After developing several innovative products, the company was starting to attract the attention of farmers looking for ways to improve their farming efficiency. However, Kinze was also drawing the attention of the industry-giant, John Deere. The following is the second installment of a five-part series describing Jon Kinzenbaw’s early battles with John Deere - both in the field and in the courtroom. What started out as suit over row unit availability, eventually ended in a ruling that forever changed Kinzenbaw’s young company - and the ag equipment industry as a whole! This excerpt is from the book "Fifty Years of Disruptive Innovation" and is told in Jon’s own words. If you missed part one, click here to catch up on this blog series. A Chance Worth Taking In 1979, I had borrowed $3.5 million for the production...

In News & PR

Kinze Manufacturing Recognizes Changes in Leadership Roles

In order to recognize evolving roles and expanding growth opportunities within the company, Kinze Manufacturing has announced several leadership role changes. Company founder Jon Kinzenbaw has assumed the role of CEO and Chairman of the Board. Susie Kinzenbaw Veatch, Jon's daughter, has been named President and Chief Marketing Officer. Brian McKown has been named Executive Vice President and COO. “My role and involvement in the company will remain the same,” said Jon Kinzenbaw. “Susie and Brian have been instrumental in working alongside me over the last number of years to develop a world class team at Kinze. These changes reflect how we are positioning the organization for future success when the agriculture market rebounds.” Along with the realignment, the company announced several additional Vice President and Director-level title changes. “Kinze has been a leading innovator in the agriculture industry for the past 51 years,” said Veatch. “I have a strong...

In Kinze News

John Deere V. Kinze Part One: the Meeting of Two Fools

Forty years ago, Kinze Manufacturing was just a small farm equipment startup near Williamsburg, Iowa. After developing several innovative products, the company was starting to attract the attention of farmers looking for ways to improve their farming efficiency. However, Kinze was also drawing the attention of the industry-giant, John Deere. The following is the first installment of a five-part series describing Jon Kinzenbaw’s early battles with John Deere - both in the field and in the courtroom. What started out as suit over row unit availability, eventually ended in a ruling that forever changed Kinzenbaw’s young company - and the ag equipment industry as a whole! This excerpt is from the book "Fifty Years of Disruptive Innovation" and is told in Jon’s own words. The Meeting of Two Fools In 1975, a farmer from southern Iowa stopped by my shop and commented that somebody should figure out how to fold...

Before You Grow: the Ultimate Spring Planting Checklist

Getting ready for planting season can, at times, be a little overwhelming, but in order to kickoff a great season a little preparation goes a long way. With that in mind, Kinze has created a simple checklist to help guarantee all of your equipment is in working order before entering the field. Give your planter a thorough inspection for loose hardware. Pay special attention to:The parallel arm boltsTransport and field wheel boltsCenter post bearing casting bolts (for lift and pivot machines)Hitch boltsEnsure the safety chain is properly installedMake sure safety lights work and SMV sign is attached, clean and visibleCheck over row units and attachments:Disc opener blade measurements (If diameter 14 1/2" or less, replace)No-till coulter adjustments and diameter (If diameter 14 1/2" or less, replace)Closing wheel bearings and alignmentCheck gauge wheel adjustment and wearCheck drive line bearing and chains. Be sure to:Make sure chains are lubricated and have the...