Here’s What Our Customers Say

Season after season. Year after year. Decade after decade. We rely on you to tell us what we’re doing right and how we can improve. Read what real Kinze customers have to say about Kinze Manufacturing throughout the years.

Kinze Electronics: a Closer Look

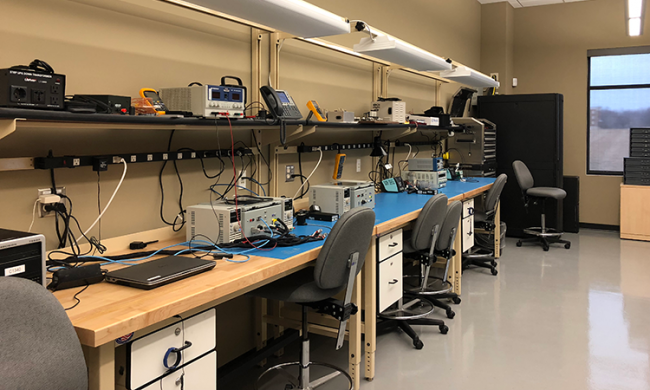

The Goal The more you can control, the better you can operate. That applies to us, too. Kinze Electronics Division was created to develop proprietary electronic systems for Kinze planters—designed, tested and supported by Kinze. This gives us total control on the products we produce so we can deliver systems that make your planter work smarter and give you more control, all while being intuitive and easy to use. The Team The Kinze Electronics team of software and electrical engineers bring over 140 years of experience from various industries including aviation, construction machinery and home electronics. Diverse backgrounds allow for out-of-the-box ideas to improve processes and ultimately, create intuitive products. Some team members grew up on farms or spent time working in agriculture. They are motivated to understand the challenges you face and create game-changing solutions to make planting easier, more productive and profitable. There is a good balance of experienced and...

In Kinze News

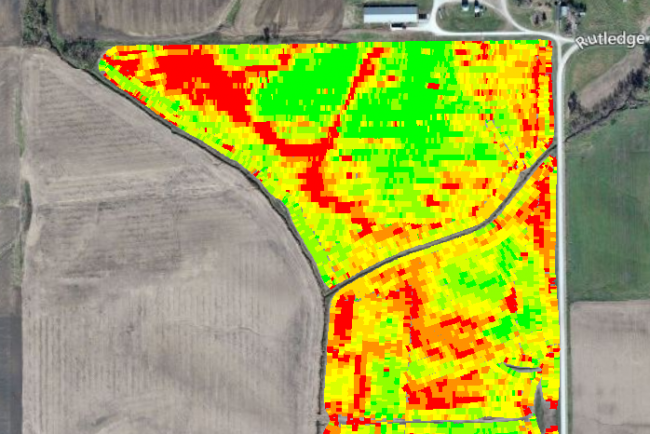

Planning With Field Data

During the growing season, there are things you can control and things you can’t. Seed options, fertilizer and population rates are examples of decisions you can control. Whereas weather and the date you get seed into the ground are outside your ability to manage. To make better decisions about controllable items, and be more profitable, collecting field and yield data has rapidly become standard practice in modern agriculture. Started in the mid-1980s by initially collecting yield results, data collection has developed to record all information from the placement of the seed in the ground, to its performance when harvested and marketed. As an overview of how data is increasingly being used to make critical crop decisions, there are three articles below on the subject: one from a university, another from a trade periodical, and the last from a manufacturer. Big Data - Purdue University Transition to Data-Driven Decisions on the Farm -...

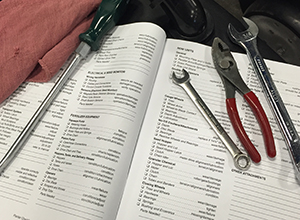

Its Time to Prepare Your Planter

In just a few weeks, tractors, planters and all other related equipment will be returning to the fields to start planting the 2018 crop. Because you put your planter away well, you have a great start getting your planter ready to be put in the dirt, however, there are still a few things you should check over. To help you get ready, many Kinze dealers host a yearly Kinze Planter Clinic, which is a great opportunity to ask questions and make sure your planter is ready for spring. Contact your local Kinze dealer to find out the date for the next clinic. In the meantime, to assist you in identifying what planter components may need to be adjusted or replaced and be prepared for a great spring, review the simple list below. Thoroughly inspect for loose hardware. Pay particular attention to:Parallel arm boltsTransport and field wheel boltsCenter post bearing casting bolts (on pivot fold planters)Ensure...

In Kinze News

, Mach Till

Prepare Your Fields Faster, Better

Prepare Your Fields Faster, Better The NEW Kinze Mach Till is a hybrid horizontal tillage tool that combines the benefits of vertical tillage, conventional tillage, and soil finishing tools into one versatile machine. The Mach Till is not a vertical tillage implement – it is a hybrid horizontal tillage tool that is quickly gaining popularity in North America. While it is a high-speed implement, running at speeds of 8 to 12 mph, that is only one of its many features and benefits – the most important benefit is what’s happening in the ground. Because it combines the benefits of many implements into one tool – it can deliver high-speed along with good soil finish and uniform residue management in clay, sand, loam, wet and dry soils. This product not only replaces many machines, but it can also be used in the fall to shred residue and again in the spring...

In News & PR

Kinze Manufacturing Adding New High-speed Disc Tillage Line

Diversification Enhances Already Strong Planter and Grain Cart Offerings Williamsburg, Iowa (Jan. 31, 2018) – Kinze Manufacturing, an industry leader in planter and grain cart equipment, is expanding its offerings with the addition of four high-speed disc tillage models, Mach Till 201, 261, 331 and 401. Susanne Veatch, Kinze president and chief marketing officer, said the new Mach Till high-speed disc products support farmer interest in faster tillage that enables them to stay ahead of the planter and be more productive by covering more acres in less time. “Farmers will now be able to obtain three types of equipment from their Kinze dealer, all with the same standard of quality,” she said. The new product line is based on a Canadian design, produced by Degelman Industries, that has been licensed to Kinze to build at its manufacturing facility in Williamsburg, Iowa. Kinze will exhibit one of its first tillage models...

In Kinze News

, Planters

Liquid and Dry Fertilizer on Kinze Planters

We know growers need options for liquid and dry fertilizer. That’s why our spectrum of products provides a variety of ways to meet these requirements at the time of planting. Both in bulk fill and row unit hopper options based on the planter model and row configurations. Our bulk fill liquid fertilizer tanks range from 300 to 600 gallon capacity depending on the model, and similarly for row unit liquid fertilizer. Dry row-unit fertilizer capacity ranges from 1,100 pounds up to 4,400 pounds. Don’t want the onboard fertilizer options? No problem. An optional rear trailer hitch for liquid fertilizer is available to tow liquid fertilizer with three or four wheel trailers behind the 3500, 3600, 3660 and 4900 planter models. Note: the tow-behind option is not compatible with squeeze pump options. Fertilizer Openers: Options for All Field Conditions Accurate placement of your seed and fertilizer is key. To your yield. To your bottom line. Disc openers...

In Kinze News

, Planters

Row Unit Attachments for Residue Management

Varying field residue is no match for Kinze planters. Across multiple soil types and tillage practices, all Kinze planters offer row unit attachments to help clear each row to plant efficiency and accurately for optimal yield. Coulter Mounted Residue Wheels These free-floating 12-inch diameter wheels have 12 curved tines with interlocked or staggered mountings. Eleven depth settings in quarter-inch increments support different tillage options and field management practices. Dual Row Unit Mounted Residue Wheels Ideal for mulch-till. Rugged spring-loaded parallel linkage. 12-inch diameter wheel, 12 curved tines with 3-position mounting to vary aggressiveness. Available on the 4000 series row units. Dawn Gfx Hydraulic Row Cleaners Maximize yield when you clear heavy crop residue from the seed trench providing consistent seed depth and crop emergence. The toolbar-mounted row cleaners are hydraulically adjustable from the cab with a control box, and provide an undisturbed, consistent row unit ride across the planter bar....

In Kinze News

, Planters

The Proven Reliability and Versatility of the Kinze 3000 Series Row Unit

Durable. Reliable. Efficient. The proven row units of the Kinze 3000 series planters are designed for farmers who want highly customizable planter options combined with simple maintenance and low cost of ownership. These proven row units are equipped with load-equalizing steel gauge wheels to provide strength, accurate seed placement, and consistent depth control – even in heavy residue or rugged planting conditions. To accommodate variable soil types and preferred tillage practices, multiple residue wheels and closing wheels are available to match your operation. An optional pneumatic down pressure package enables operators to adjust settings on the go for consistent plant emergence to get the most yield possible from every acre. Farmers count on their equipment to stand up to the tough demands of planting season. The 3000 series row unit scores high marks for durability with a hardened seed tube guard and scraper for opener blades, as well as molded wheel covers to minimize...

In Kinze News

, Seed Meter

Which Meter Drive is Right for You?

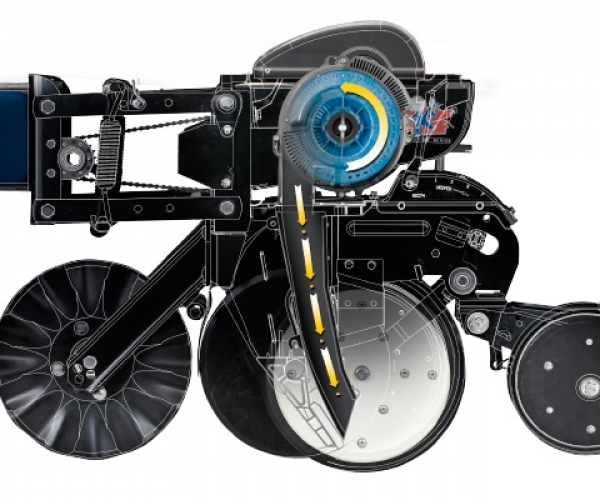

Advances in planter technologies have dramatically changed metering drives through the years. Today’s planters can be equipped with anything from a simple ground contact drive to a state-of-the-art electric drive completely controlled by GPS. So which one is best for your planter? Kinze provides options for what meter drive is best suited to maximize yield performance on each farmer’s operation. Electric Meter Drive In 2013, Kinze provided the industry-first electric drive on the model 4900 planter. The electric drive on this innovative planter allows control of each row. Seed populations are fully adjustable as set up on a prescription map to minimize seed costs and maximize yields. Maintenance is simpler, since there are no drive shafts, chains, clutches or gearboxes. In 2018 Kinze introduced the next generation Blue DriveTM electric drive system controlled by the Blue VantageTM display. When going through waterways and entering headlands, each row unit can be turned on and off as needed to stop the...

In Kinze News

, Seed Meter

Which Seed Meter is Right for You?

A Brief History of Seed Meter Technology It used to be, when farmers went to the field to plant, the planting monitor on the tractor was equipped with simple indicator lights. These lights showed whether or not seeds were actually getting to the ground. If a seed tube became plugged, a monitor alarm would sound and the problem could be solved. This technology helped, but it was limited. It only enabled the farmer to monitor activity, without actually measuring anything. During the late 1990s and mid-2000s, significant improvements were made to tube sensors and monitors. For the first time, real-time data was being delivered to the farmer so that corrections to seed population could be quicker and easier. Singulation—how well the meter drops seeds one by one—was introduced. Accuracy percentage, measured in real time, took into account the number of skips and doubles. Today, planting speeds have increased. There are...