Editorial provided by Chris Schlesser, Kinze District Manager

I remember the first time I saw Kinze’s new 4000 series vacuum meter. The one with electric drive. At the time, they called it “Project Echo,” one of several top-secret innovations being developed at Kinze.

Rumors had been circulating for months with all sorts of possibilities. Electric drive. Instant population rate changes, infinitely variable. Incredibly accurate seed singulation, placement and spacing, even on turns. Reduced seed velocity at the exact point of release. One disc for multiple seeds. 99%+ accuracy! That one really got my attention!

And, I remember thinking “how in the world could they make that kind of statement, and claim that kind of accuracy, even in this day of precision technology?” However, NOTHING prepared me for what I was about to see when I saw it on the test stand.

First of all, I couldn’t believe what they were doing. Kinze didn’t run it with just one specific seed shape or size of rounds, bigs, smalls, treated, non-treated, etc. They threw them all into the same test batch; then started the test at what’s typically considered the recommended planting speed… five miles per hour. It was amazing. For minutes, singulation accuracy rarely dropped below 99.5%, even with junk seed. Then they ramped the planting speeds up to 8-, 10- and 12 mph. At 8 mph, it rarely dropped. Even at 10 and 12, it exceeded my highest expectations … tracking in the 98.5-99.5% range!!

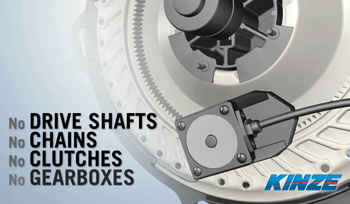

Then I realized what was missing. PRACTICALLY EVERYTHING … everything I was accustomed to seeing. Clutches. Sprockets. Gearboxes. Driveshafts. In fact, the only moving part on the entire metering system was the seed disc powered by the electric drive. I saw them adjust the seed singulator with a simple click of a knob. I saw perfect 3 o’clock seed drop into the tube; for near-perfect velocity as the seed was released and I saw near-perfect consistency as it exited the seed tube.

And I’m thinking, it doesn’t get any better than this. Next, they rolled out the new cast iron row unit with top-quality USA-produced castings and steel gauge wheels. Designed for maximum side-load strength and durability, especially in no-till. Kinze quality. Precision tooled and built. Plus, unmatched versatility with 12” row unit travel to handle steep slopes and terraces. Absolutely no short-cuts.

Get the picture? I’m selling the best metering system in the field today. I know it, because I’ve seen it work. I have plenty of tests to prove it. Competition can rig whatever test they want, and promote whatever advantage they can manufacture, but the real bottom line is this: When you look at performance – on the test stand or in the field – it doesn’t get any better than Kinze!